twice the life means half the cost.

about 50 million metric tons of electronic waste have been recently created in just one year (tiseo, 2021). this results in an amount of about 500 million metric tons of e-waste in 10 years, with the devices continuing to have an average lifetime of 4 to 5 years (elder, 2019). however, if the lifetime of the product gets doubled, only one instead of two electronical devices need to be produced and thrown away in 10 years, ensuing in the quantity of e-waste being halved.

this results in a halved amount of processed materials, in a halved amount of energy needed for the production and distribution, and in a halved amount of co2 emitted during the whole process.

therefore, the extension of a product’s lifetime is a crucial part of improving a product’s environmental performance. (karana et al., 2014)

the "better world architecture", which has already been mentioned in our previous article "the key is the architecture", describes our patented new product line for sustainable premium quality remote controls. for its development, expanding the products lifespan has consequently been one of several major aspects.

with the outer shell’s material of the new product architecture being 50 times more abrasion resistant compared to traditional plastics material, while being made of 45% renewable materials, no unsightly scratches will hinder a long use of the product.

having passed all our strict material quality tests, the product will not be damaged by falling onto the floor or by being exposed to direct sunlight.

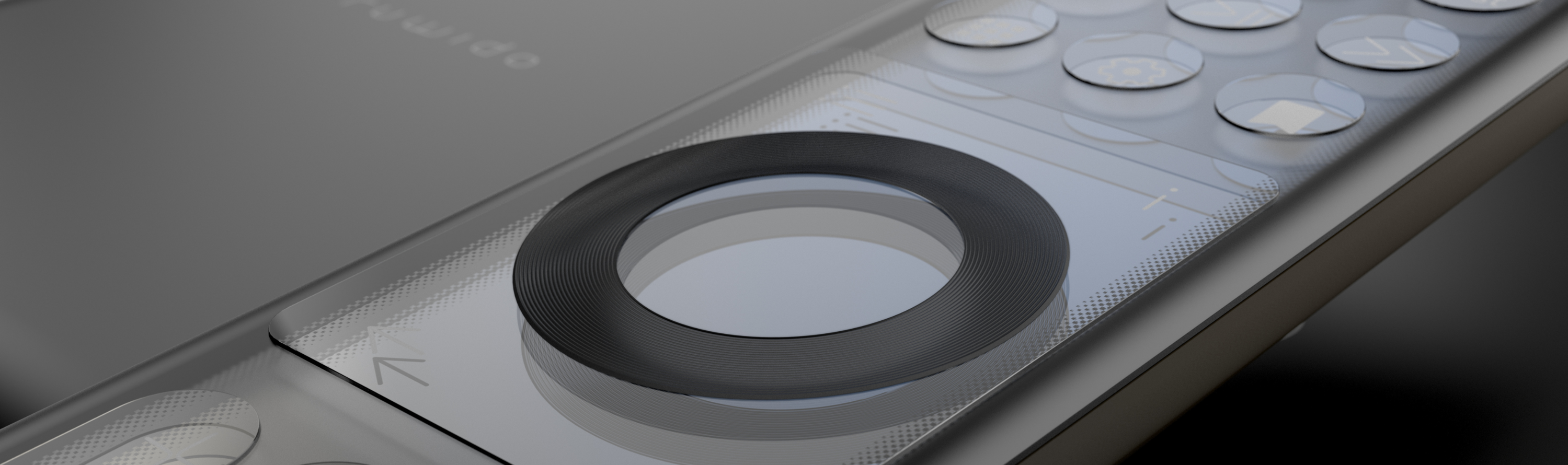

the architecture’s one-piece haptic layer provides safe and clean encapsulation of the pcb and thus perfectly protects the electronic parts from dust and liquids.

this makes the product safe from crumbly crisps or spilled cola, resulting in a longer lifespan of it’s inner parts and thus the whole remote control.

if a remote control is not needed by a user anymore because of a change of an iptv contract for example, the ideally protected pcb can be reused as it is for a new remote control, saving about 50% of co2 of the new remote control’s production. (lettner, 2022)

as the product does not contain a high number of parts, is not glued together and is not impurified by any lacquers, the outer plastic parts are made for being recycled for at least three times.

through our refurbishment model, used remote controls can be remanufactured to become like new ones. used plastic parts can be re-granulated, and poured into a new shape. electronics can be tested and reused. this way, about 80% of the total life cycle carbon footprint can be saved without recognisable quality losses.

having achieved such an extension of the lifespan of individual materials and of the entire product, precious resources can be conserved, and energy can be saved. because for the product’s environmental impact the same thing applies as for the customer’s money:

using a product twice the time costs half the price!

Elder, Rodney. (2019). Creating New Markets in the Lifecycle of Connected Things. blog.equinix.com/blog/2019/02/11/creating-new-markets-in-the-lifecycle-of-connected-things/;

Karana, E., Pedgley, O., Rognoli, V. (2014). Materials experience : fundamentals of materials and design. Oxford : Butterworth-Heinemann.

Lettner, M. (2022). REPORT: Screening Life Cycle Assessment and environmental hot spot analysis for remote control.

Tiseo, Ian. (2021). Global E-Waste - Statistics & Facts. www.statista.com/topics/3409/electronic-waste-worldwide/